That is, for the boiler to overshoot by a few degrees, once it has reached the set temperature, and by those means bringing the return temperature to the set point is the only way of avoiding it to cycle more.

Once the boiler stops burning, the temperature of the outgoing water drops almost immediately to the return temperature, so to avoid it turning on again, the return should be close to the set temperature, and that is what the boiler is doing, thereby keeping the water in the whole system at the set temperature, and not at the return temperature that happen to be there when the set temperature was first reached... (I hope someone can make sense of all this rambling...)

The system , with the DIY OpenTherm master, has now been running for a few days, with no problems, and quite an accurate temperature in the rooms. The PID controller just needs some small adjustments in order to converge a bit quicker, and converge always (I sometimes have 0.2 degrees below the set point, which is no big deal anyway...)

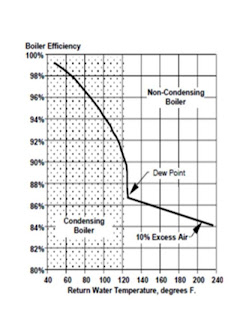

I found a few graphics depicting the boiler efficiency as a function of the return temperature. Here are a few, all in Fahrenheit (didn't find any in C):

|

| http://www.mnshi.umn.edu/kb/scale/boilers.html |

|

| http://blog.triangletube.com/blog/hydronic-heating-solutions/outdoor-reset-maximizes-spring-energy-savings |

|

| http://www.navitron.org.uk/forum/index.php?topic=9066.0 |

The last is not the efficiency, but the relation of water temperature to outside temperature that I am using. I use a curve near the "1" curve.